CLICK HERE FOR LIFTING BEAM PRICING

Lifting Beams – Skid-Steer/Forklift Attachment

- A safe and convenient attachment for handling rebar and rebar cages.

- A popular attachment with metal building contractors.

- Used for handling long metal building beams as well as sheet metal roofing and siding.

- Universal Fit – “slip-on-forks” – Designed for use with rough terrain forklifts, either straight

mast or extendable reach. - It comes equipped with fork pockets that will accept up to 7” wide x 3” thick forks.

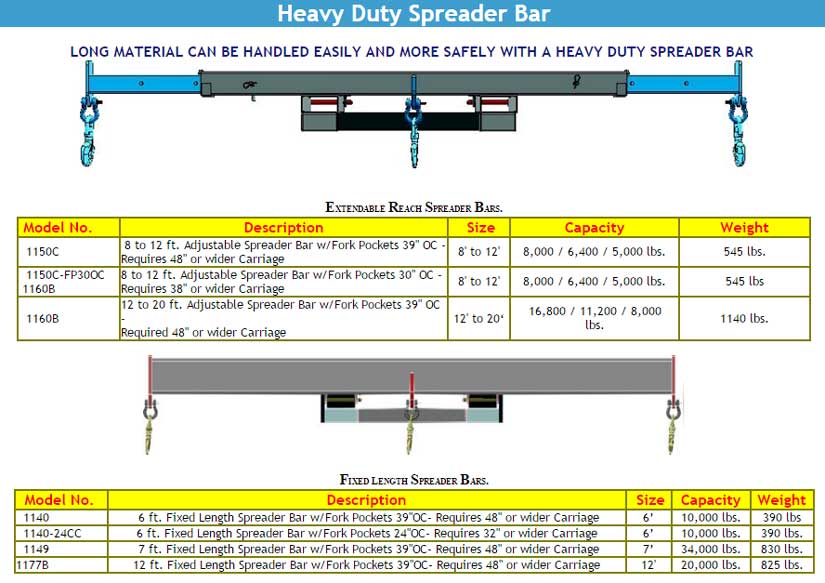

Any long material that has a tendency to bend can be handled easily and more safely with a Easy Rack spreader lifting beam.

For A FREE Lifting Beam Quote Cal 888-775-3720

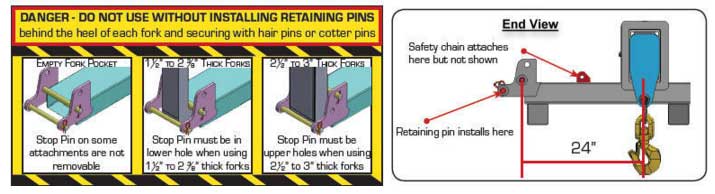

Danger – do not use without installing retaining pins behind the heel of each fork and securing with hair pins or cotter pins. Safety chain(s) must also be used. Wrap chain around a strong part of the fork carriage and secure with locking grab hook.

Spreader Bar is designed for use with rough terrain forklifts of adequate capacity to safely handle the load. It comes equipped with fork pockets that will accept up to 7” wide X 2 ¾” thick forks. Dual center holes provide hook points that also allows the spreader bar to be suspended from a crane. This manual however, is targeted to its use on rough terrain forklifts.

Be aware that the information contained in this manual is intended as a guide and does not replace the need for the user to know, understand, and observe all applicable company, local, state, and federal safety codes and or requirements. The model 1160 meets/exceeds the requirements of ASME B30.20-2006 and is classified as Category A and Service Class 0 as defined in ASME BTH-1-2005

Before Use:

1) Make sure the operator is well qualified to operate the specific forklift model to be used, has read and understands this manual and has reviewed the forklift operator’s manual for any additional requirements, limitations, restrictions, or additional safety procedures prescribed by the forklift manufacturer when using this type of attachment. The forklift operator must also be properly certified under OSHA requirements to operate the forklift to be used.

2) Inspect the spreader beam to make sure it is in good condition. There must not be any broken welds, nor any deformation of the steel tube or other component, nor any cracks in the steel. The telescoping members should move in and out freely. Inspect swivel hooks and shackles to make sure they are complete, are in good condition, and shackle anchor screw pins are screwed in tight. Make sure the spreader bar width adjustment pins are in place and have hair-pins installed to secure them. Check to make sure the fork retaining pins have hair pins to secure them in place and safety chains are properly secured to anchor blocks and grab hooks are properly secured. Decals showing “Empty Weight”, “Read Before Using” and “Rated Lift Capacity” are required. Check that all decals are in place and legible. Replacement decals are available from Easy Rack.

3) Make sure personnel involved understand any hand signals that will be required and all involved personnel understand what will be required of them.

4) Make sure the travel path is clear of obstructions and that adequate clearance will be maintained from all power lines Caution:

5) Risks are high for serious injury when working around suspended loads. The operator must avoid carrying the load over people and it is best to have a 10′ foot rule. This requires that no one is allowed to be within 10 feet of the area in which the load would fall if a failure occurred.

6) Do not allow anyone to ride on the spreader beam nor on the load being carried.

7) Do not make any repairs or modifications to the spreader bar without written authorization from the manufacturer. Replacement of hooks, shackles, decals and hair-pins does not require authorization. Installation: On the forks installation: Insert the forks into the fork pockets and then slide the spreader bar all the way onto the forks so the pin tabs extend behind the back of the fork. Insert the fork locking pins in each side and secure them with hair-pins to lock the spreader bar to the forks.

Then secure the safety chains to a strong part of the forklift carriage making sure the chains are not slack and installed as close to a straight horizontal pull as possible. The chain angle must not exceed 45 degrees. Suspended from a hook: The spreader bar can be attached to hooks thru the top holes in the crown plates. It is recommended that the hooks have keepers to help secure the spreader bar. If the hooks are too large, shackles may be required to make the connection. Adjust the width: Adjust the bar to the desired width by removing the adjustment pins and sliding out the inner section of the bar.

The bar can be set for 12, 16, or 20 foot widths. There is a stop to prevent the inner section from being slid all the way out of the center tube however the spreader bar must not be used pulled all the way out to the stops. The inner section must be slid in far enough to align the holes so the width adjustment pins can be installed and secured with a hair-pin. The bar must be extended an equal distance on both sides. Rated Capacities: Rated capacities shown below also appear on the spreader bar decal(s).

Be aware that these capacities are for the spreader bar itself and do not in any way reflect the capacity of the forklift. Refer to the forklift operator’s manual for capacity ratings and any limitations or restrictions when using this type of attachment. Remember the weight of the bar must be deducted from the lift capacity of the forklift. If there is any question as to forklift’s lifting capacities when using this attachment, contact the forklift manufacturer for clarification. Never exceed the rated capacities of the spreader bar except for purpose of a test and then do not exceed 125% of its rated capacity. Never exceed the capacity of the forklift.

Make sure also that the load rating for slings, chains, or straps used with the spreader are equal to or exceed the rating of both the forklift and the spreader bar, if not; always limit the load to the lowest rated part of the lifting system. RATED LOAD CAPACITY OF MODEL 1160 SPREADER BAR Empty Weight – 1100 lbs. At 12 feet wide 16,000 lbs Extended to 16 feet wide 11,000 lbs Extended to 20 feet wide 8,000 lbs

Pingback: Lifting Beams – How To Lift Large Awkward Items Safely? | Office Furniture & Material Handling Equipment