Edge Dock Levelers

When do buildings need dock levelers?

When do buildings need dock levelers?Whenever they do not have docks that match the height of today’s truck. Over the years, trucks have become much taller. Standard beds average a height of 52-53” and refrigerated beds range from 54-55”. Older buildings may have docks as low as 45”-49” and require some sort of dock leveler equipment to facilitate fork truck traffic from the dock to the truck.

What is an “edge of dock” leveler?

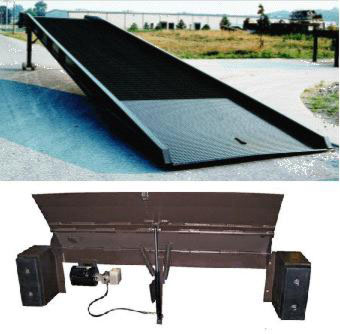

An edge of dock leveler attaches to the side of the dock, extending its range by 5” vertically and 5” horizontally. This means that if a dock is 49” in height, an edge of dock unit can enable it to access trucks measuring 54” in height. They are much more economical than pit mounted loading dock levelers, which have to be embedded in the concrete itself and represent a considerable cost for a retrofit.

How does an edge of dock leveler work?

When a truck backs up to the EOD leveler, two rubber bumpers stop it in precisely the right position. The ramp is then into position with a tool known as a ratchet riser. This bridges the distance between the dock equipment and the bed of the truck so forklifts, fork trucks, pallet jacks, and workers can cross over. With refrigerator trucks, it is normally necessary to install a refrigerator lip on the edge of the ramp to extend it an additional three inches into the truck bed.

What is the difference between a lo-dock leveler and an edge of dock leveler?

A lo-dock leveler is a factory add-on that increases the height differential of an edge of dock unit. In some older buildings, the dock height is significantly less than that of today’s modern trucks. Buildings that were built in the 40’s and 50’s may have docks as low as 45”-48”. The problem with using an edge of dock leveler alone is that it will only add 5” to this height—an insufficient amount. For buildings like this, Easy Rack can arrange to add a lo-dock leveler to an edge of dock unit. Such a unit can then add up to 11” total to any dock height, effectively overcoming the 5” limit of standard edge of dock levelers.

How much weight can an edge of dock leveler handle?

Most edge of dock levelers will handle capacities between 20,000 and 25,000 pounds. Many are manufactured with a self-storing handle that makes them easy to position by pulling the handle to the dock floor. The latch assembly activates the lip forward to the floor of the trailer when the handle is lifted, and the handle automatically returns to the stored position when it is released. Edge of dock levelers include bumpers and bumper blocks and can be custom manufactured in widths of 72” and 78” per request.

If you can not find what you are looking for call us toll free at 1-888-776-3720 and we will find it for you.

Our main office is deep in the heart of Texas with associates located throughout the United States that enable us to service all 50 states including New York NY, Los Angeles CA, Miami, FL. Chicago, IL. Denver CO., New Orleans, La., Cleveland, Ohio, Kansas City, Mo., Mesa, Arizona, Virginia Beach, Va., Omaha, Nebraska, Oakland, California, Miami, Florida, Tulsa, Oklahoma, Minneapolis, Minnesota, Colorado Springs, Colorado, Arlington, Texas, Beaumont, Texas, Denton, TX, McKinney, Texas, Midland, TX, Killeen, Texas, Dallas TX DFW, San Antonio, TX, Austin, TX, ALBQ, NYC, LA, MPLS.

Labels: Commecial Loading Dock Supply Company, Commercial Loading Dock Lifts, Loading Dock Equipment, Loading Dock Levelers, Loading Dock Lifts, Loading Dock Lights, Loading Dock Ramps

Electric lifts reduce workplace trauma and injury resulting from repetitive motions, bending, and lifting. They are also highly ergonomic and efficient tools for improving process flow. By speeding up production, processing, and shipping, they add value to an organization’s profit. By minimizing stress and injury,

Electric lifts reduce workplace trauma and injury resulting from repetitive motions, bending, and lifting. They are also highly ergonomic and efficient tools for improving process flow. By speeding up production, processing, and shipping, they add value to an organization’s profit. By minimizing stress and injury,