Brick, Mortar & Block Carts

Brick and block carts are designed to help masons in residential construction move brick and block into areas where there is no forklift access. This is very common in the home building industry, where there simply is no way to move a forklift into what will eventually be a home interior. Also, many home builders feel that forklifts are beyond their budget and choose to look for less expensive ways to move equipment around the site. Brick and block carts are remarkably efficient tools for this task, and they are affordable for even the smallest of family owned construction companies to invest in.

Brick and block carts are designed to help masons in residential construction move brick and block into areas where there is no forklift access. This is very common in the home building industry, where there simply is no way to move a forklift into what will eventually be a home interior. Also, many home builders feel that forklifts are beyond their budget and choose to look for less expensive ways to move equipment around the site. Brick and block carts are remarkably efficient tools for this task, and they are affordable for even the smallest of family owned construction companies to invest in.The brick and block cart is much safer and far more ergonomic than brick barrows. It is also helps move materials much more quickly. The reason for this is simple. Bricks and blocks tend to come stacked and banded. In order to transport them in a barrow, you have to cut the bands, stack them in the barrow, then unload and restack them after they are moved. This wastes considerable time on the job, which in turn results in a waste of money.

Brick and block carts allow you to move hand truck entire stacks of banded brick and block without having to undo the bands. Simply run the forks into the bricks and tilt the unit back. This will allow you to pick up as many as two bands of brick at a time and comfortably transport them to the work area. It is not necessary to hand stack or unstuck the bricks, so an enormous amount of time can be saved. Furthermore, it is much easier on your back because you do not have to stoop down to load and unload bricks like you do when using a barrow.

Most masons simply wheel the brick and block cart to the work area and stand it up in a vertical position with the bricks still held in place by the forks. They then cut the bands at the top and use from the stack however many bricks they needs. For scaffold work, brick and block carts can be placed right under the scaffold, and bricks can hand stacked on the scaffold as needed.

Easy Rack sells brick and block carts in two different model: the Rough Terrain Brick Cart and the Deluxe Rough Terrain Block/Brick cart. The Double Back Plate model features an additional pair of 15” forks specifically designed to handle any block package.

We see the greatest use of these carts in single story construction projects where forklifts are simply too expensive to purchase or lease, and where the work area itself is considerably smaller than that around larger homes. Having a convenient, ergonomic tool like the Easy Rack brick and block cart allows for quick mobility, safe labor, and rapid turnaround on the project. In fact, many companies who invest in brick and block carts, as well as other space saving and ergonomic tools by Easy Rack, are often able to lower their contract costs and win more bids by passing their material handling savings on to the general contractor.

If you are looking for a brick and block cart or a material handling cart of any type. Easy Rack has just what you are looking for.

Here are just a few of the many material handling equipment we carry:

Mobile Carts

Having mobile carts in place for staff to move goods and equipment with will ensure that all goods into the business are treated properly, and safely......

Platform Carts

The one tool that comes in handy under almost any different commercial and industrial circumstance is the platform cart. These hardy transportation devices are one of the most common sights in warehouses and factories all over the world......

Platform Trucks

One of the main advantages that heavy duty, aluminum, metal, plastic & folding platform trucks have over other carts is the sheer size of load that they are able to carry......

Push Carts

Push carts come in a wide variety of different forms, and have been designed to fulfill a number of different roles within the workplace. Whether you need to be able to carry a single heavy weight around and cannot find the appropriate resource for a forklift......

Rolling Carts

For light duty use throughout the workplace, rolling carts serve a number of functions, and are flexible enough for use in most situations......

Warehouse Carts

In a warehouse environment, there are always hundreds of jobs that need doing in order to ensure the greatest possible efficiency. From the careful distribution of items throughout the warehouse through to the actual picking of orders from the shelves......

If you can not find what you are looking for contact us toll free at 1-888-776-3720 and we will find it for you.

Our home office is located in Houston, Texas with warehouses located throughout the United States that enable us to service all 50 states including Memphis, Tennessee, Baltimore, Maryland, Irving, Texas, Amarillo, TX, Brownsville, Texas, Grand Prairie, TX, Pasadena, Texas, Fort Worth, Texas., El Paso, Texas., Charlotte, N.C, Milwaukee, Wisconsin, Seattle, Washington, Boston, Massachusetts, Denver, Colorado, Louisville-Jefferson County, Kentucky.

Labels: Block Carts, Brick and Block Carts, Brick Carts, Brick Hand Trucks, Hand Trucks, Masonry Equipment, Material Handling Carts, Material Handling Products

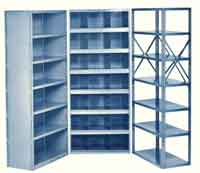

Used commercial steel shelves

Used commercial steel shelves