Storage Shelving

Storage shelving units enable facility managers to convert unused space into valuable storage and organization space. Workers complete tasks faster when they can access materials quickly, safely, and easily. Companies often find these results in a significant reduction of man-hours and the elimination of overtime hours. Storage shelving also can potentially convert sufficient vertical cube space into storage space that a facility that was previously overcrowded now has plenty of room to continue operating, and the need to relocate no longer exists. Keeping overhead at a minimum and helping companies avoid the expenses of moving are just two examples of how storage shelving units can generate a tangible return on investment for organizations that invest in them.

Storage shelving units enable facility managers to convert unused space into valuable storage and organization space. Workers complete tasks faster when they can access materials quickly, safely, and easily. Companies often find these results in a significant reduction of man-hours and the elimination of overtime hours. Storage shelving also can potentially convert sufficient vertical cube space into storage space that a facility that was previously overcrowded now has plenty of room to continue operating, and the need to relocate no longer exists. Keeping overhead at a minimum and helping companies avoid the expenses of moving are just two examples of how storage shelving units can generate a tangible return on investment for organizations that invest in them.Storage shelving systems can be used for storing almost any item or container that has a flat bottom surface. The bulk of our 18 gauge and 20 gauge steel wire shelves can easily handle 400-450 lbs in weight. Weight capacity is not the factor to consider when making a purchase, however. It is equally important to balance the load you are storing as it is to support the load. Otherwise, storage shelves can become imbalanced toward the front and tip over during use. To prevent this hazard, calculate the total length, width, and height of the total items you plan to store. The wider the crate or box, the more physical shelf area you will need to evenly distribute the load.

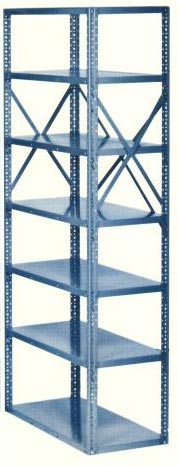

Easy Rack used commercial storage shelving is available in open backed models and closed back models. Both bring specific benefits to different environments and tasks. For smaller items that do not weigh very much, open backed systems provide plenty of support and allow workers to retrieve materials from the front, back, or even the sides of the shelves. Open back storage shelving is often used inside offices to store file boxes containing invoices, tax documents, and employee records. They are ideal for storing office supplies when you run out of closet space, or for storage in portable buildings that have no closets. Closed back shelves or custom made shelving are more stable because they partly rest against the wall. This reduces the risk of tipping and also helps conserve floor space.

If you intend to store very heavy crates, machine parts, or heavy containers, it is vest to overestimate the amount of weight capacity you will need and invest in an industrial strength storage shelf, rivet shelving or a wide span system. Employees may not be aware of the amount of weight already stored on the unit, and they may inadvertently add more materials than the unit can handle. This often happens when people are in a hurry. Industrial shelves are designed to minimize the risk of tipping, but overloading them will cause them to bow in the middle and reduce unit lifespan. Planning ahead will prevent this from occurring. When calculating weight capacity, always purchase storage steel shelving that allows room for growth and allows for contingencies and human error as well.

Also, please be aware that shelving dimensions refer to the total L x W x H measurements of the steel components, not the actual cubic storage space. As in the case of weight capacity, it may be necessary to purchase the next size up to give your facility the cubic storage you need for all of your materials. You can also call an Easy Rack material handling expert and look into having a custom unit built along to special dimensions.

Easy Rack carries a wide variety of commercial shelving, material handling equipment, commercial lighting, used pallet racks, and modular prefab buildings installed nationwide.

If you can not find what you are looking for call us toll free at 1-888-776-3720 and we will find it for you. Our home office is located in Houston, Texas with warehouses located throughout the United States that enable us to service all 50 states including New Orleans, La., Cleveland, Ohio, Kansas City, Mo., Mesa, Arizona, Virginia Beach, Va., Omaha, Nebraska, Oakland, California, Miami, Florida, Tulsa, Oklahoma, Minneapolis, Minnesota, Colorado Springs, Colorado, Arlington, Texas, Beaumont, Texas, Denton, TX, McKinney, Texas, Midland, TX, Killeen, Texas, ALBQ, NYC, LA, MPLS.

Labels: Material Handling Equipment, Pallet Flow Rack Systems, Steel Storage Mezzanines, Storage Cantilever Rack, Storage Shelving, Storage Shelving Installation, Warehouse Cantilever Shelving

Used cantilever racks

Used cantilever racks