No. Many people use the two terms synonymously, but the term industrial really means that these material handling products are used in storage areas, factories, and warehouses. Both light weight and heavy duty models feature the same basic design: two forks that slip under a pallet, lift it off the ground, and allow it to be moved to another location. Most pallet trucks now have forks that adjust laterally so that pallets can be gripped from the inside prior to being lifted.

What types of power do they use?

Some are completely manually powered, with a hydraulic jack that is pumped by a handle, and the unit is pushed or pulled by hand. However, newer designs now feature power assisted units that get the wheels moving so that the operator does not have to strain to create sufficient force to start them rolling. Many powered units operate on gas or electric power and do all the lifting, forward motion, and reverse motion automatically.

Which type is better?

If you invest in an ergonomic manual model, you can easily move a load weighing over two tons safely. The advantage of using an industrial pallet jack that has no motor is that it has fewer complex parts that can fail. However, no matter how ergonomic such a unit is, there is still a certain amount of physical force that is required to move the jack and the load. With electric and/or gasoline powered pallet trucks, you never have to use any physical force to lift or push the unit. Also, the user friendly controls make maneuvering the pallet more like driving a vehicle than pushing a large load with a tool.

Are the powered, heavy duty models worth the investment?

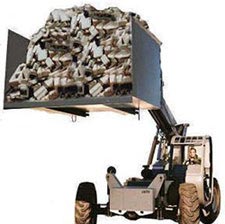

If you have very large loads, or oddly sized loads, yes. You’ll find that electric or gas powered units are easier to maneuver in all directions. This improves process flow by minimizing collisions, and it is far safer for the operator as well because there is no need to apply muscle power to moving the load.

Do you have industrial pallet jacks for specialized applications?

Yes. Some industries, like the food distribution industry or the pharmaceuticals industry, require clean rooms for storage and processing. We recommend using stainless steel pallet trucks for these areas. There are also pallet jacks made for moving long materials safely in a lateral as well as linear direction, and units that feature built in scales.

Is an industrial pallet jack a heavy duty pallet jack?No. Many people use the two terms synonymously, but the term industrial really means that these material handling products are used in storage areas, factories, and warehouses. Both light weight and heavy duty models feature the same basic design: two forks that slip under a pallet, lift it off the ground, and allow it to be moved to another location. Most pallet trucks now have forks that adjust laterally so that pallets can be gripped from the inside prior to being lifted.

What types of power do they use?Some are completely manually powered, with a hydraulic jack that is pumped by a handle, and the unit is pushed or pulled by hand. However, newer designs now feature power assisted units that get the wheels moving so that the operator does not have to strain to create sufficient force to start them rolling. Many powered units operate on gas or electric power and do all the lifting, forward motion, and reverse motion automatically.

Which type is better?If you invest in an ergonomic manual model, you can easily move a load weighing over two tons safely. The advantage of using an industrial pallet jack that has no motor is that it has fewer complex parts that can fail. However, no matter how ergonomic such a unit is, there is still a certain amount of physical force that is required to move the jack and the load. With electric and/or gasoline powered pallet trucks, you never have to use any physical force to lift or push the unit. Also, the user friendly controls make maneuvering the pallet more like driving a vehicle than pushing a large load with a tool.

Are the powered, heavy duty models worth the investment?If you have very large loads, or oddly sized loads, yes. You’ll find that electric or gas powered units are easier to maneuver in all directions. This improves process flow by minimizing collisions, and it is far safer for the operator as well because there is no need to apply muscle power to moving the load.

Do you have industrial pallet jacks for specialized applications?Yes. Some industries, like the food distribution industry or the pharmaceuticals industry, require clean rooms for storage and processing. We recommend using stainless steel pallet trucks for these areas. There are also pallet jacks made for moving long materials safely in a lateral as well as linear direction, and units that feature built in scales. round a store or warehouse.

Increase productivity and create a safe work environment with a portable solution. The following are six examples of when it is time to buy trailer loading ramps for a temporary or permanent warehouse need:

Increase productivity and create a safe work environment with a portable solution. The following are six examples of when it is time to buy trailer loading ramps for a temporary or permanent warehouse need: Increase productivity and create a safe work environment with a portable solution. The following are six examples of when it is time to buy trailer loading ramps for a temporary or permanent warehouse need:

Increase productivity and create a safe work environment with a portable solution. The following are six examples of when it is time to buy trailer loading ramps for a temporary or permanent warehouse need: