|

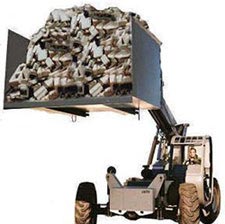

Lift truck dumpsters are a type of forklift attachment. They are essentially large hoppers that are filled with various types of debris. Pockets and safety chains allow them to lock to the forks of a fork lift in order for the operator to lift, transport, and then dump the hopper’s contents into a dumpster or similar container for collecting refuse. Lift truck dumpsters are a type of forklift attachment. They are essentially large hoppers that are filled with various types of debris. Pockets and safety chains allow them to lock to the forks of a fork lift in order for the operator to lift, transport, and then dump the hopper’s contents into a dumpster or similar container for collecting refuse.

There are many different types of forklift hoppers. These lines feature different load capabilities, dumping mechanisms, and weight capacities. All are made from heavy gauge steel, the strength of which varies from model to model. Some of the most heavy duty models can transport up to 3 tons of debris in a single load.

A lift truck dumpster is easy and safe to use. The hopper is first positioned flat on the ground so that a licensed fork truck operator can drive the forks into the pockets and secure them to the structure. Workers then load the hopper to maximum capacity with debris, and the operator lifts the hopper above eye level in order to have sufficient visibility to drive the vehicle. A safety lock prevents the forklift attachment from dumping its contents prematurely as it bumps over uneven terrain. Once it is positioned above the dumpster, the operator can either release the contents with a rope or a latch release lever located on the side of the unit.

We sell lift truck dumpsters to all sorts of industrial facilities. In the warehousing industry, self-dumping hoppers play a vital role in keeping the areas around freight yards free of debris. Another large user group is the recycling industry. With more and more recycling collection centers being built all over the country, forklift attachment hoppers play an important role in moving recycling materials like plastic bottles, glass, cardboard, and metal from the collection areas to large trucks that carry them off to recycling plants. Dockyards also use these forklift attachments to separate debris from products that are brought in on ships. Various applications for these units are also found in factories, refineries, chemical plants, and distribution centers.

The most common use of self-dumping hoppers, however, is probably found in the construction industry. Construction sites have so much debris that the grounds must be cleaned up several times a day. The best way to accomplish this is with a lifting device that will elevate the debris safely and efficiently transport it to dumpsters so crews and vehicles can move about more freely and safely.

We recommend investing in lift truck dumpsters whenever large pieces of debris, or very heavy loads of debris, need to be moved quickly. The cost of manual transport is too high, and often it is too dangerous. Smaller loads that can be safely pushed by hand can be transported with hopper carts, and even traditional, simply tools like wheelbarrows can be used to haul light scrap metal and dirt. However, heavy debris requires a lifting mechanism that can get it into the dumpster without causing strain to workers or spills. Fork truck hoppers have proven themselves to be the most effective means of dumping things like heavy steel scrap, tree stumps, concrete, wood scrap, and concrete scrap.

|