LED Parking lot lighting fixture kits are some of the most convenient and effective commercial lighting supplies we offer. Ideal for saving time and money, parking lot kits allow lighting designers and industrial clients to light their parking facilities with poles, posts, fixtures, lamps, and accessories that are already pre-configured to work together and tested to ensure full government compliance with foot-candle minimums and restriction on glare and light pollution.

During daytime, a normal business parking lot is illuminated perfectly by the sun—visibility is clear and safety worries held to a minimum. But, at night parking lots can be a dangerous place altogether, and if a parking lot is not well-lit after the sun goes down, customers will not feel secure and may avoid a business for this reason alone.

It is a widely known fact that Poorly lit parking lots attract crime, including vehicle break-ins, robberies, property crimes, and much worse. The poor visibility of dark parking lots also presents other safety issues, such as an increased likelihood of vehicle accidents. In addition, customers often believe a businesses to be closed when parking lots are not well-lit and may drive to another lighting store to do business, might cost businesses revenue over and over again.

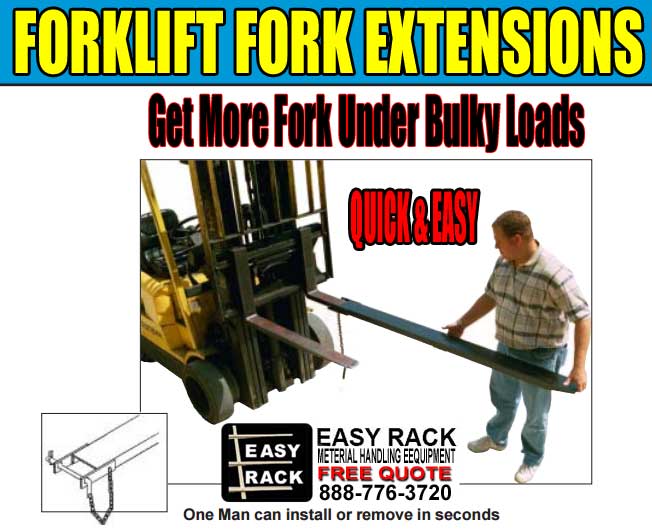

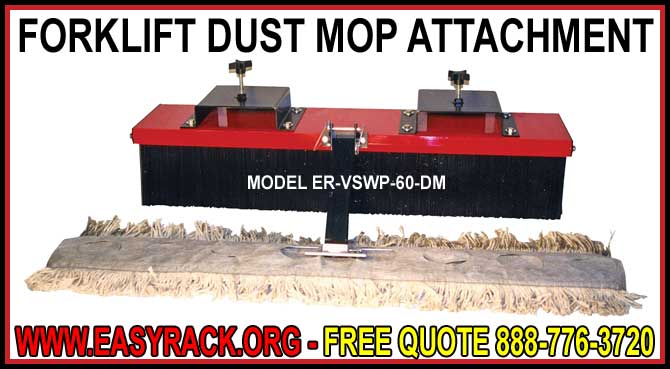

EASYRACK.ORG FREE QUOTE 888-776-3720

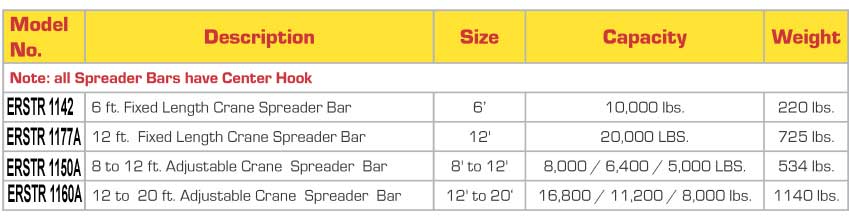

Adjustable Crane Spreader Bars —

Adjustable Crane Spreader Bars —

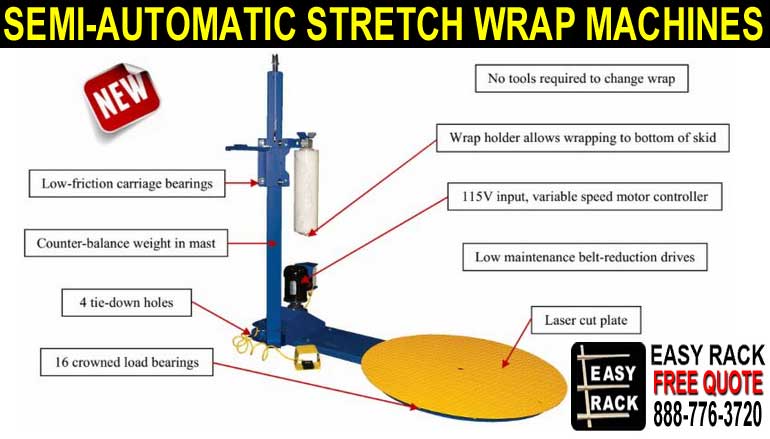

Standard Shrink Wrap Machine Features

Standard Shrink Wrap Machine Features