Aluminum Loading Dock Ramps

It may be unrealistic for you to install a permanent loading dock in your facility due to the current recession. A more economical alternative to concrete, permanent docks is one or more aluminum loading ramp(s). Aluminum loading ramps are built to be both stable and portable, and can provide all of the functionality of a full-sized permanent dock at only a fraction of a cost.

It may be unrealistic for you to install a permanent loading dock in your facility due to the current recession. A more economical alternative to concrete, permanent docks is one or more aluminum loading ramp(s). Aluminum loading ramps are built to be both stable and portable, and can provide all of the functionality of a full-sized permanent dock at only a fraction of a cost.You might have heard that only steel ramps are sturdy enough for heavy loading dock operations. This is a myth. Aluminum ramps are designed to handle both heavy payloads and human foot traffic. In fact, they can handle the same amount of weight as their steel counterparts--approximately 16,000 lbs to 30000 lbs. You can safely drive fork lift trucks up these ramps into trucks and operate a remote shipping yard or construction site just like a warehouse loading dock.

Even though aluminum is a lightweight metal, it can be reinforced to enable it to safely support high weight capacities. This combines the benefit of a relatively light ramp that is highly portable with a structural durability that can reliably withstand a beating during heavy productions times.

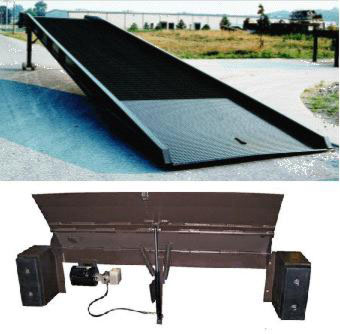

Heavy duty strength is not the only advantage you receive from an aluminum loading ramp. A number of key safety features are built into aluminum loading ramps that make them safe for workers to walk over while pulling pallet racks or carrying materials by hand. A 1 ½ʼ curb provides guidance up the ramp and prevents pallet rack and forklift roll offs. It is also important to keep the ramp from swaying to one side or the other while workers are walking up the incline. Safety chains anchor the ramp in place to keep it fixed in position. Rubber shock absorbers underneath the aluminum ramp prevent heavy loads from bouncing it up and down. Diamond-shaped grating on the surface of the deck provides extra traction for wheels and work boots, making the surface more slip resistant in rainy weather.

Because aluminum loading ramps and equipment are used so much in remote locations, it is also important that the by highly mobile. Portability, therefore, another key benefit you can expect to add to your rail yard or construction site with these remarkable tools. Because they are much lighter than steel equivalents, they can be pulled much more easily behind a fork truck attached to a tow bar that can be optionally attached to the ramp at the time of manufacture. They are also light enough for one worker to adjust manually by means of a hand-crank hydraulic pump that raises or lowers the ramp into position.

Easy Rack carries a wide variety of loading dock equipment, used pallet racks, commercial shelving, material handling equipment, commercial lighting,and modular prefab buildings installed nationwide. If you can not find what you are looking for call us toll free at 1-888-776-3720 and we will find it for you.

Our loading dock equipment company is located in Houston, Texas with warehouses located throughout the United States that enable us to service all 50 states including New York NY, Los Angeles CA, Miami, FL. Chicago, IL. Denver CO., New Orleans, La., Cleveland, Ohio, Kansas City, Mo., Mesa, Arizona, Virginia Beach, Va., Omaha, Nebraska, Oakland, California, Miami, Florida, Tulsa, Oklahoma, Minneapolis, Minnesota, Colorado Springs, Colorado, Arlington, Texas, Beaumont.

Labels: Aluminum Loading Dock Ramps, Commecial Loading Dock Supply Company, Loading Dock Equipment, Loading Dock Levelers, Loading Dock Lifts

Exactly what are portable docks?

Exactly what are portable docks?

Commercial loading docks and material handling

Commercial loading docks and material handling